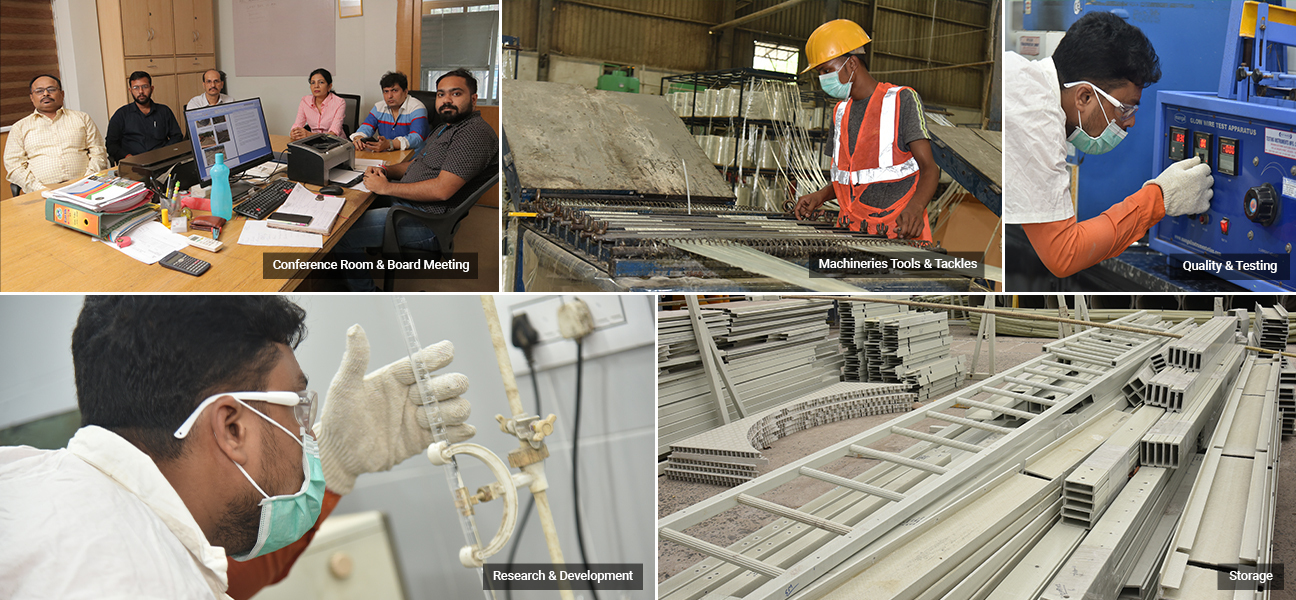

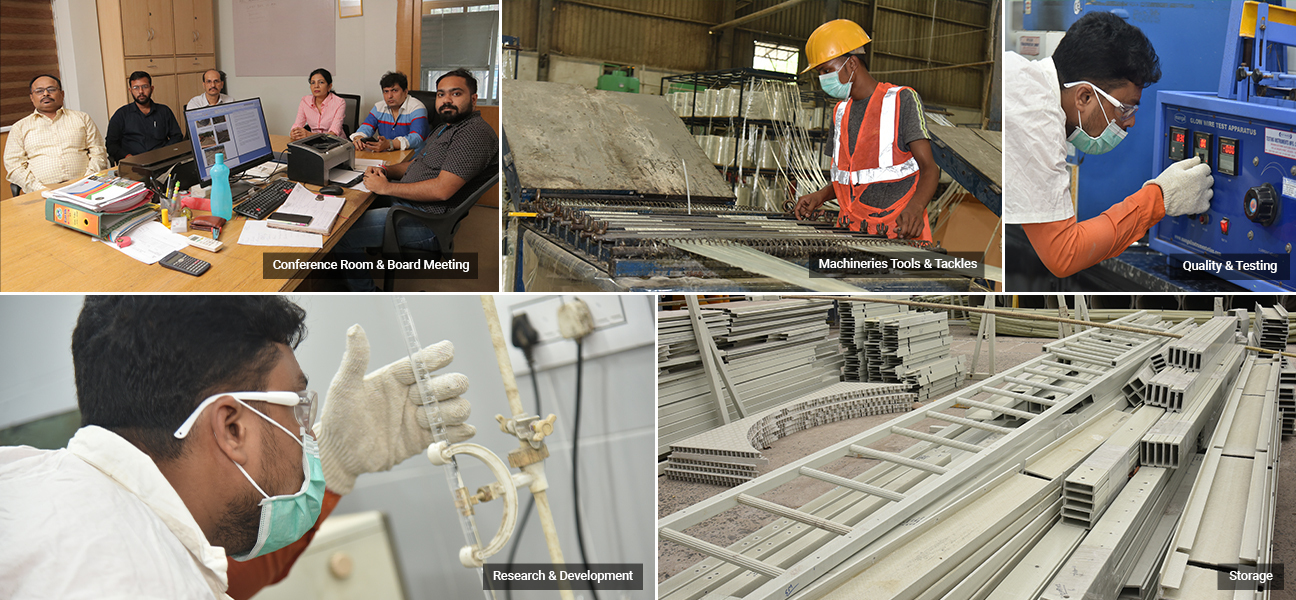

At ARC Insulations, quality is embedded into every aspect of our operations – from raw material procurement to state-of-the-art manufacturing and stringent product testing. Our relentless pursuit of quality ensures our GFRP composites deliver exceptional performance, safety and longevity.

Projects

Workers

Years of Excellence

Offices