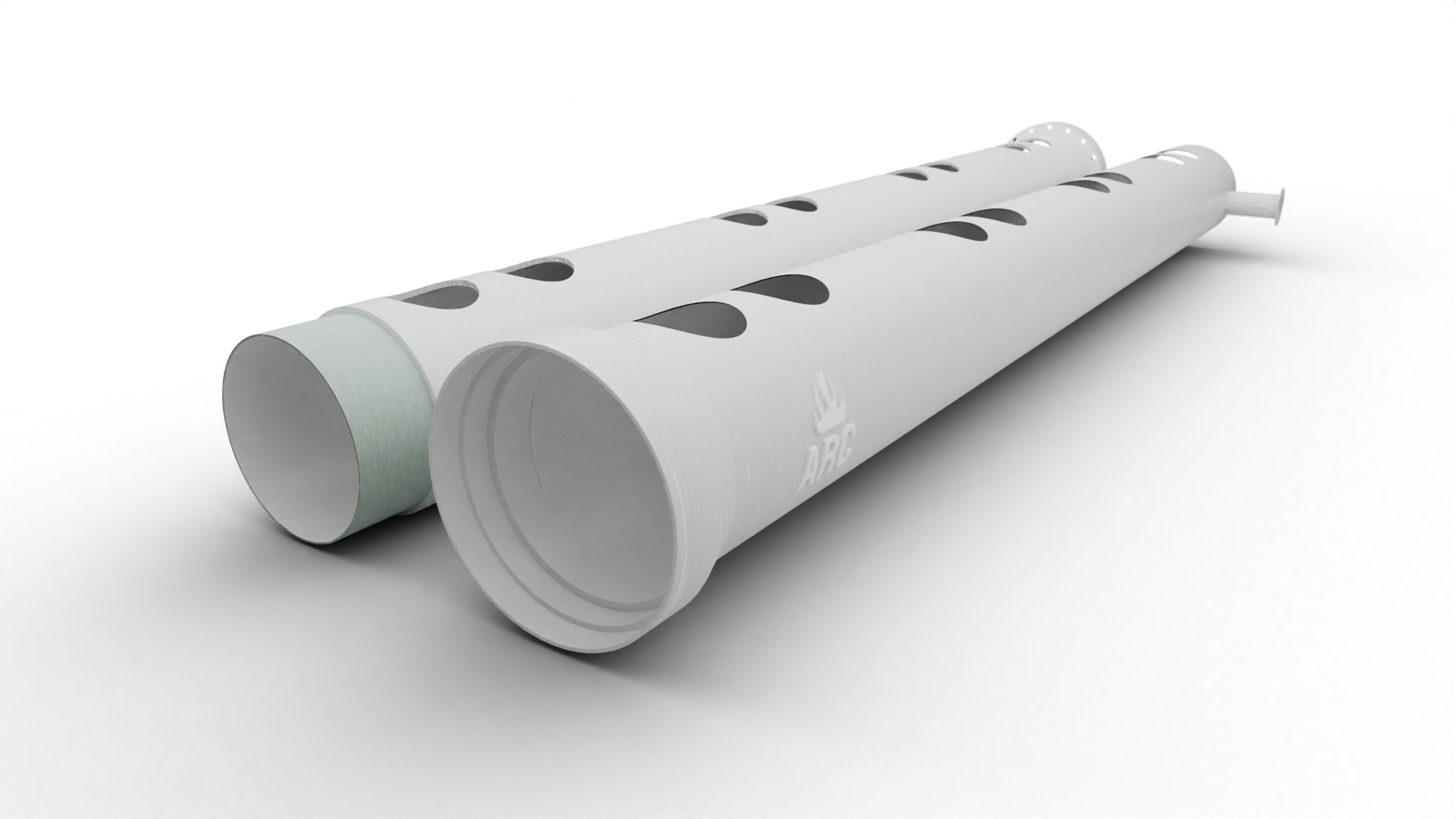

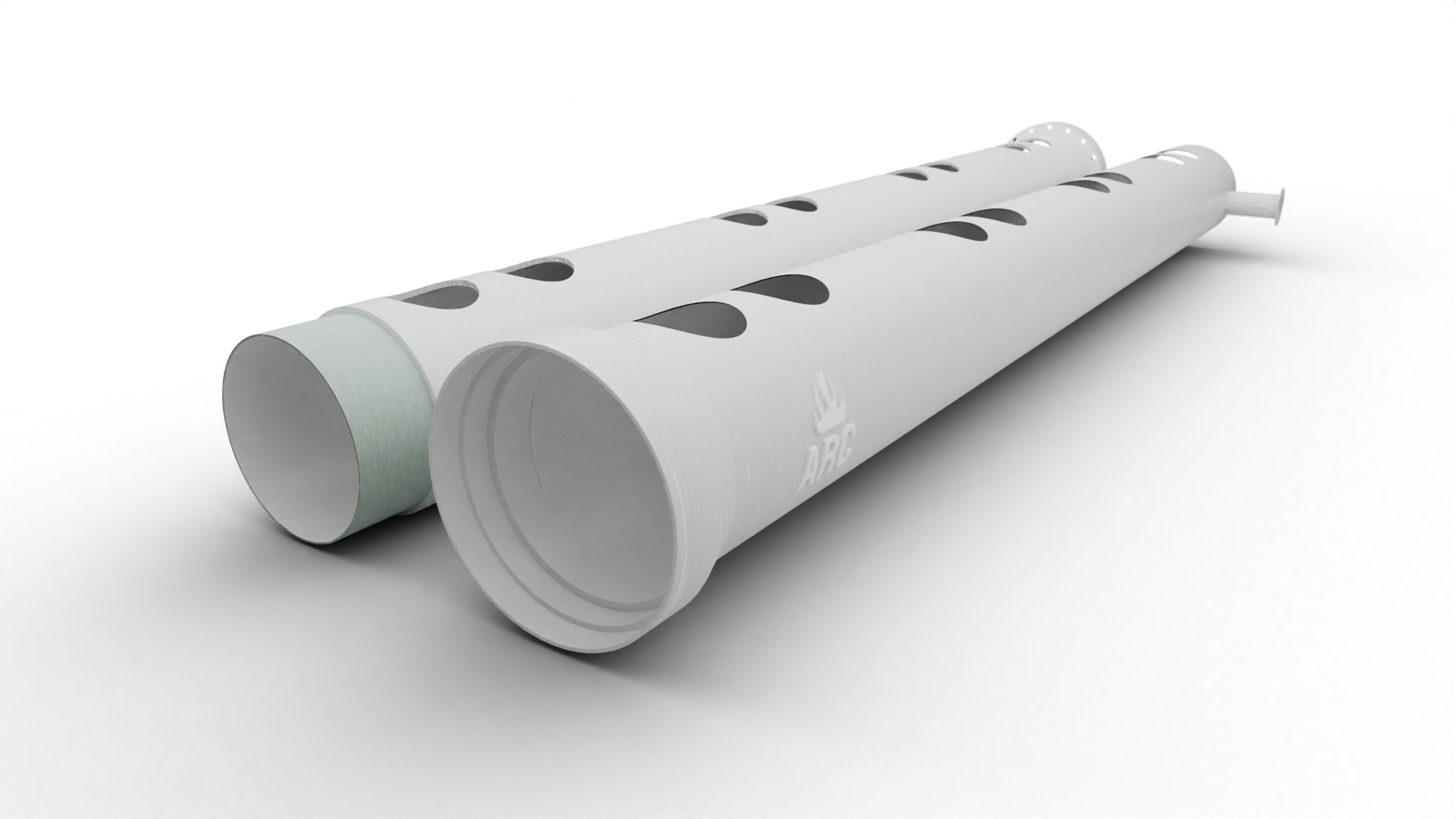

Fiberglass-reinforced plastic (FRP), also known as glass-reinforced plastic (GRP), is a composite material made of a polymer matrix and fibres for reinforcement. So a pipe made of FRP material using the contact moulding or filament winding methods is called a FRP pipes or GRP pipes. Specific FRP pipe qualities are obtained in the finished product by using a variety of resin types, including thermosetting polyester, epoxy, phenolic resin, and others. “E-glass” glass fibre is the most often utilised reinforcement.

Worldwide use of the FRP/GRP piping system as a corrosion-resistant substitute for copper piping has been noted. Internal lining, external coating, and cathodic protection can all be readily eliminated by choosing FRP as the pipe material. A wide variety of diameters for FRP pipe or GRP pipe systems are available.

FRP pipes are highly resistant to corrosion from a wide range of chemicals, including acids, alkalis, solvents, and saline environments. This ensures longer service life and reduced maintenance costs compared to traditional metallic pipes.

FRP pipes can withstand high temperatures encountered in various industrial processes, maintaining their integrity and performance in demanding environments.

Resistant to fouling, scaling, and buildup, FRP pipes require minimal maintenance, translating to lower operational costs and fewer disruptions.

FRP pipes offer excellent strength-to-weight ratios, making them easier to install and handle, reducing installation costs and the need for heavy support structures.

FRP pipes can be customized in various diameters, lengths, and configurations, allowing for specific design requirements. They can handle a wide range of pressures and temperatures.

FRP pipes have low thermal conductivity, helping maintain the temperature of transported fluids, reducing heat loss or gain, and improving overall process efficiency.

They can be designed to meet fire-resistant specifications, suitable for areas with high fire risk.

The lightweight and flexible nature of FRP pipes facilitates easier installation, particularly in cramped or hard-to-access areas.

FRP pipes are resistant to impact, UV radiation, environmental factors, and marine growth, ensuring long-lasting performance in various environments.

They are resistant to a wide range of chemicals, including those used in cooling tower water treatments and sewage processes, preventing leaks and failures caused by chemical attacks.

Made from renewable resources, FRP pipes have a lower carbon footprint compared to metal pipes and do not leach harmful chemicals into the water.

They can be tailored to meet specific project requirements, such as pipe diameter, wall thickness, and fittings, with various joining methods available.

This feature reduces friction and minimizes pressure drops, leading to improved flow, reduced energy requirements for pumping, and enhanced overall system efficiency.

| Property | Test method | Pipe N/sq. mm |

|---|---|---|

| Ultimate hoop stress | ASTM D 1599 | 250 N/mm2 |

| Long Terms Hydrostatic Strength for 50 Years | ASTM D 2992 B | 172 M/mm2 |

| Axial Bending Modulus | ASTM D 2529 | 12000 N/mm2 |

| Hoop Bending Modulus | ASTM D 2412 | 18000 N/mm2 |

| Property | Test Method | Pipe N/mm² |

|---|---|---|

| Axial Tensile Stress | ASTM D1599 | 75 N/mm2 |

| Hoop Tensile Stress | ASTM D1599 | 480 N/mm2 |

| Poisson Ratio Hoop/Axial | ASTM D1599 | 0.35 |

| Poisson Ratio Axial/Hoop | ASTM D1599 | 0.58 |

| Property | Pipe |

|---|---|

| Co efficient of Liner Thermal expansion | 1.6×10-5 cm/cmo C |

| Density | 1.9 Kg/cm2 |

| Electrical Resistivity | 1014 ohm/cm |

| Di Electric Constant | 3 – 4 F/cm |

| Thermal Conductivity | 3 – 4 F/cm |

ARC FRP products come with an in-house test certificate documenting performance, quality, and compliance based on internal testing and evaluations.

Download

ARC FRP products come with an in-house test certificate documenting performance, quality, and compliance based on internal testing and evaluations.

Download

ARC FRP products come with the Bureau Veritas test certificate verifying independent assessment of their quality, performance, and adherence to industry standards.

Download

ARC FRP products come with the Indian Register of Shipping test certificate verifying independent assessment of their quality, performance, and adherence to industry standards.

Download

ARC FRP products come with the TUV SUD test certificate verifying independent assessment of their quality, performance, and adherence to industry standards.

Download

ARC FRP products come with the Tata Projects Limited test certificate verifying independent assessment of their quality, performance, and adherence to industry standards.

Download

ARC FRP products come with the TUV India Private Limited test certificate verifying independent assessment of their quality, performance, and adherence to industry standards.

Download