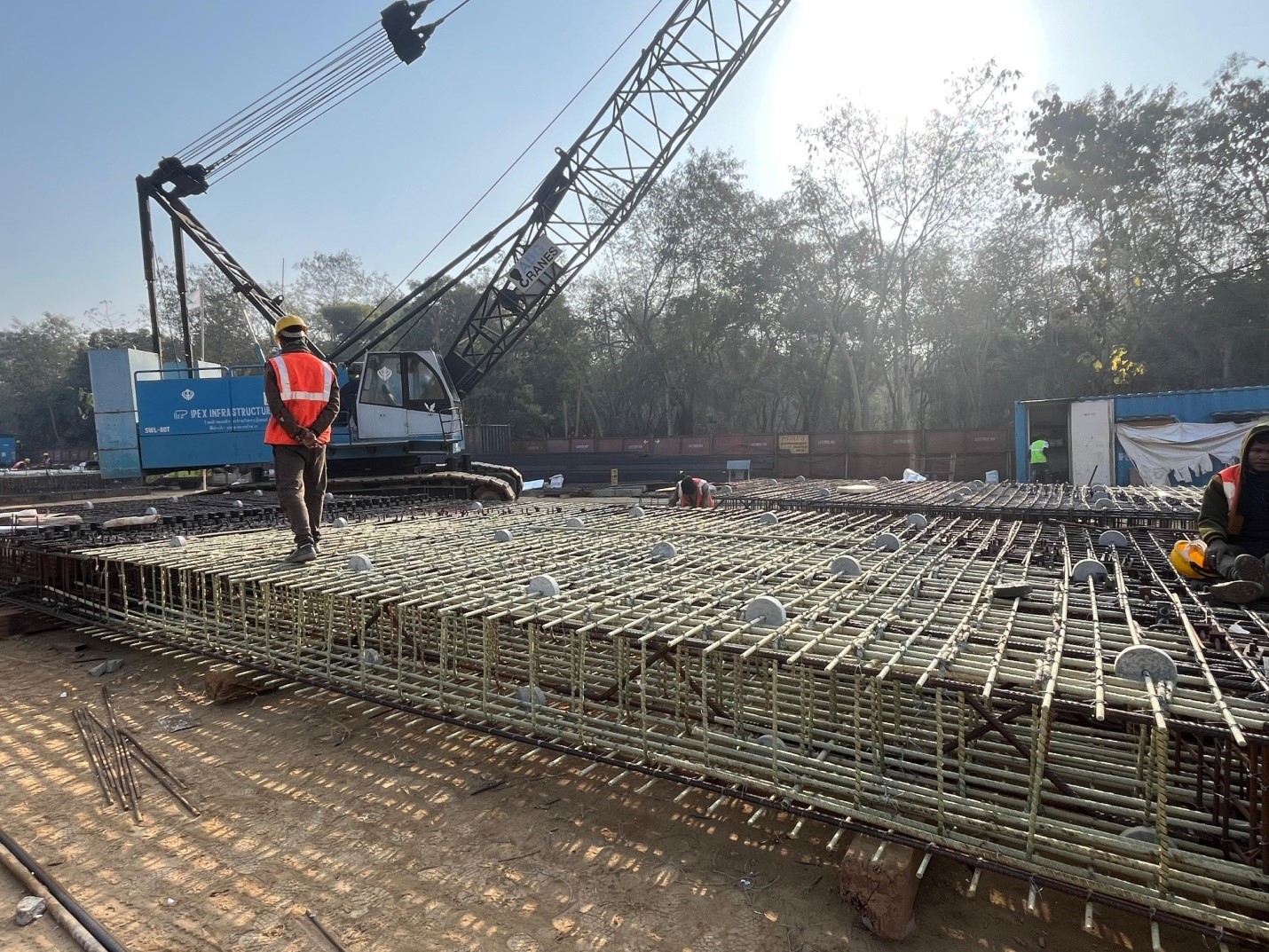

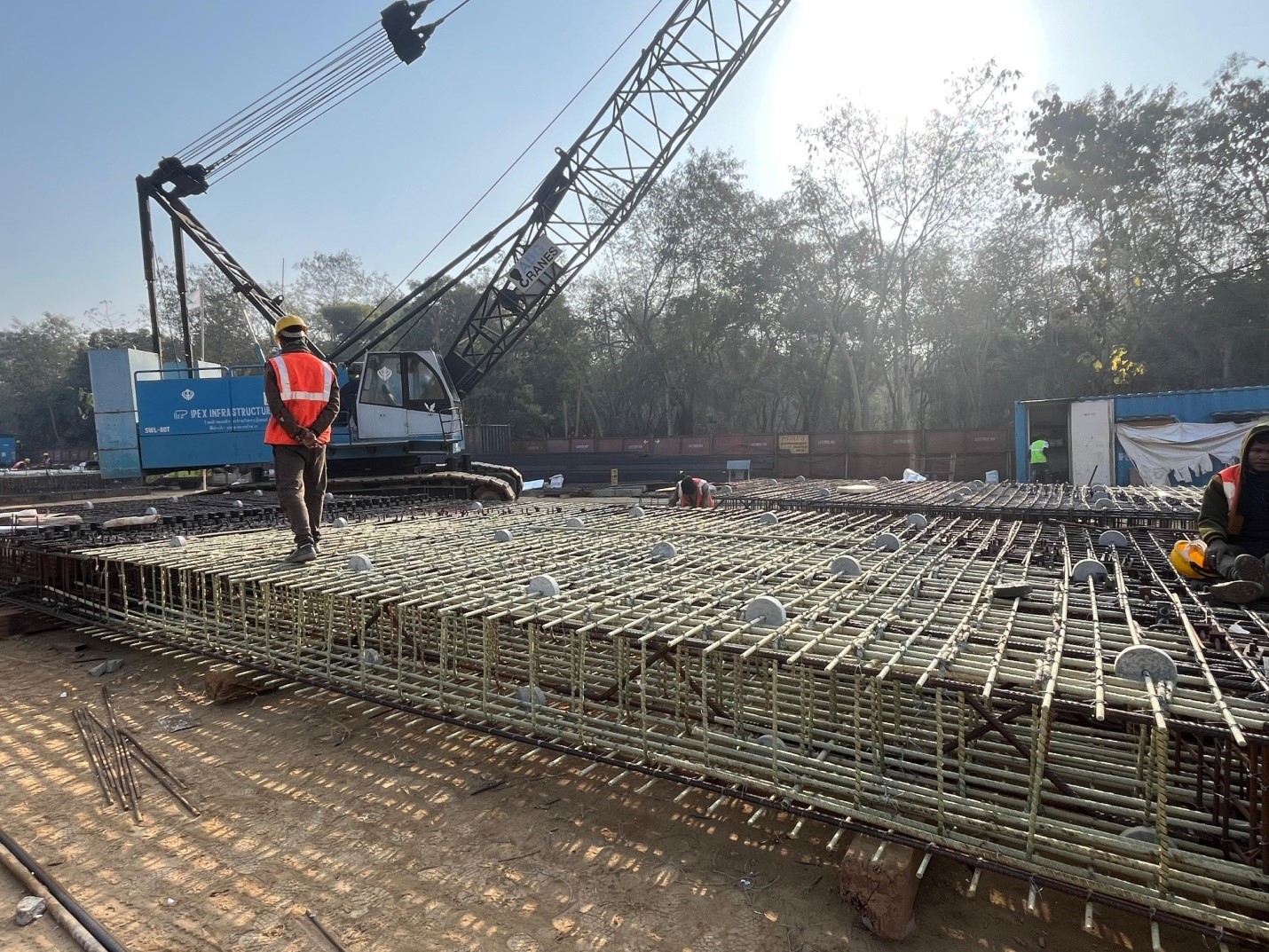

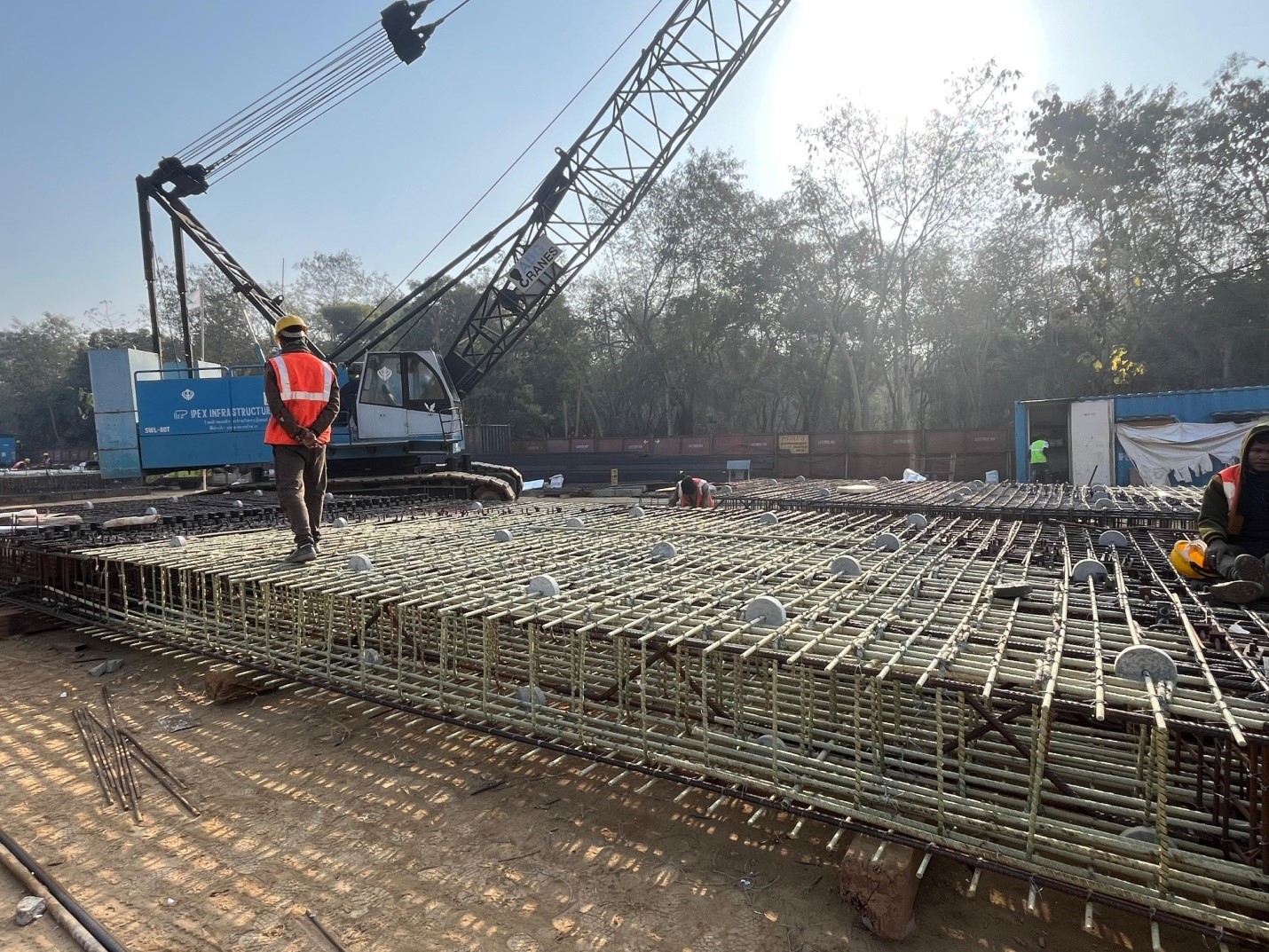

ARC Rebar & Bends in Diaphagram Wall

Benefits of using GFRP Rebar in Bends in Diaphragm Wall Construction:

- Corrosion Resistance: GFRP rebar is inherently resistant to corrosion and electrochemical degradation, ensuring long-term durability and structural integrity in diaphragm walls exposed to harsh environments such as marine or brackish water.

- Extended Service Life: By eliminating the risk of rust and corrosion, GFRP rebar significantly extends the lifespan of diaphragm walls, reducing maintenance costs and the need for frequent repairs or replacements.

- Lightweight and High Strength: GFRP rebar offers a high strength-to-weight ratio, making it lighter than steel reinforcement yet maintaining excellent tensile strength. This facilitates easier handling, lowers transportation costs, and improves the efficiency of diaphragm wall installation.

- Non-Conductive Properties: The non-conductive nature of GFRP bars eliminates the risk of stray current-induced corrosion, enhancing the durability and reliability of reinforced concrete diaphragm walls near electrical installations or cathodic protection systems.

- Improved Structural Integrity: GFRP rebar’s corrosion resistance minimizes the risk of concrete cracking and spalling caused by reinforcement corrosion, ensuring the long-term integrity and load-bearing capacity of diaphragm walls.

- Reduced Embedment Length: GFRP rebar’s high tensile strength and bond characteristics allow for reduced embedment lengths compared to traditional steel reinforcement, potentially reducing overall construction time and costs.

- Resistance to Fatigue: GFRP rebar exhibits excellent resistance to fatigue, making it suitable for diaphragm walls subjected to cyclic loading conditions, such as those in marine structures or foundations.

- Cost Savings: Incorporating GFRP rebar in diaphragm wall construction results in significant cost savings over the structure’s lifecycle due to reduced maintenance and repair needs, as well as potential savings in installation costs.

- Sustainable Construction: The use of GFRP rebar promotes sustainable construction practices by reducing the carbon footprint associated with maintenance and replacements, and minimizing environmental impacts related to corrosion issues.

- Versatility: GFRP rebar is adaptable for various diaphragm wall applications, including curved configurations, offering design flexibility and meeting project-specific requirements effectively.