ARC is the largest GFRP (FRP) rebar manufacturer in India, with 12 years of industry experience, specializing in GFRP (Glass Fiber Reinforced Polymer) rebar- a type of FRP rebar. We operate 14 machines for straight GFRP rebars and 4 machines for GFRP bend rebars, with a monthly production capacity of 700 tons. ARC boasts comprehensive in-house testing facilities adhering to ACI-440.1R-15 and BIS 18256-2023 standards. Currently, ARC offers GFRP straight bars in diameters ranging from 4mm to 50mm and bent stirrups from 6mm to 25mm.

GFRP rebar stands for Glass Fiber Reinforced Polymer rebar and is a specific type of FRP rebar used in concrete structures as an alternative to traditional steel rebar. GFRP rebar is made of glass fibers embedded in a polymer resin matrix, typically vinyl ester or epoxy resins. The glass fibers provide tensile strength, while the polymer resin binds the fibers together.

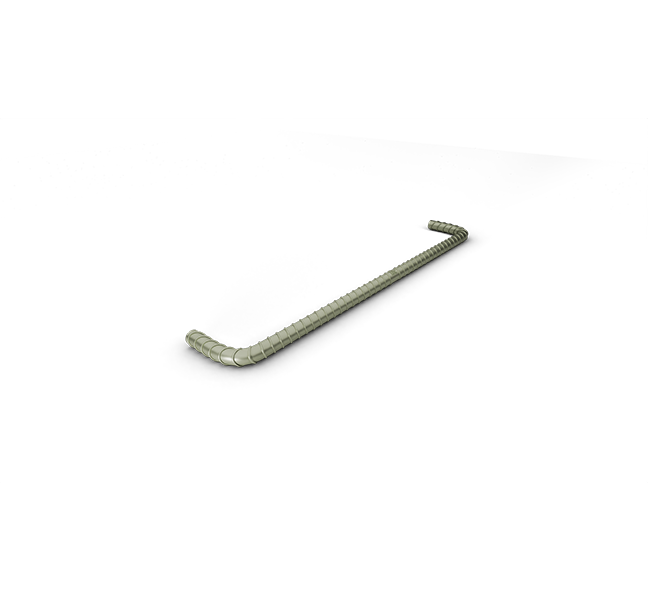

GFRP (Glass Fiber Reinforced Polymer) rebars are manufactured using an extrusion process, which can produce both straight and bent rebars. The manufacturing process involves two distinct forms, each tailored to meet specific requirements.

Once the desired bend shape is achieved, the partially cured GFRP rebar is subjected to a controlled heating process, typically in an oven or a heated molding setup. This post-bending heat treatment fully cures and solidifies the polymer matrix, locking in the desired shape and ensuring the rebar’s structural integrity.

Glass Fiber Reinforced Polymer rebar resists corrosion and electrochemical degradation, ensuring long-term durability and structural integrity in harsh environments such as marine, soil, or urban settings.

By eliminating rust and corrosion risks, GFRP rebar extends the lifespan of structures like boundary walls, roads, foundations, and tanks, reducing maintenance and repair costs.

With a high strength-to-weight ratio, GFRP rebar is lighter than steel but maintains excellent tensile strength, facilitating easier handling, reduced labour costs, and more efficient construction processes.

The non-conductive nature of GFRP rebar prevents stray current-induced corrosion, enhancing durability in areas with electrical installations or cathodic protection systems.

Using GFRP rebar results in substantial cost savings over the lifecycle of structures due to reduced maintenance and repair needs, as well as potentially lower installation costs.

GFRP rebar supports environmentally conscious practices by reducing the carbon footprint associated with frequent repairs and replacements, contributing to greener construction solutions.

The corrosion resistance of GFRP rebar helps prevent concrete cracking and spalling, maintaining structural integrity and load-bearing capacity in foundations, columns, beams, and other elements.

GFRP rebar is suitable for various applications, including boundary walls, concrete roads, foundations, piles, retaining walls, and underground tanks, providing design flexibility and adaptability.

GFRP rebar’s high tensile strength and elastic behavior improve the seismic performance of structures, offering increased ductility and energy dissipation capacity.

The lightweight nature of GFRP rebar simplifies handling and installation, improving construction efficiency and reducing the risk of errors.

GFRP rebar’s corrosion resistance prevents unsightly rust stains and spalling, maintaining the aesthetic appeal of structures over time.

GFRP rebar’s excellent fatigue resistance makes it suitable for cyclic loading conditions, such as those found in marine structures or bridges.

In underground tanks, GFRP rebar helps improve leak resistance by minimizing the risk of concrete cracking and spalling caused by reinforcement corrosion, ensuring better watertightness.

ARC GFRP Rebars are non-magnetic and contain no IONS. Hence are ideal reinforcement for areas close to magnetic apparatus – such as hospital MRI rooms, Electronic testing devices and certain high-voltage applications.

ARC FRP rebar outperforms steel with twice the tensile strength and up to seven times lighter weight. Unlike steel, it is rustproof, ensuring greater durability and reduced maintenance. It provides superior performance and longevity in harsh environments compared to traditional steel rebar.

2X the tensile strength compared to steel

Up to 7x lighter in concrete flatwork applications 4x lighter compared to the same size diameter

Fiberglass rebar will never rust, enabling more durable structures

| Characteristic | Reinforced-Bar | |

|---|---|---|

| Steel A-Ill | ARC GFRP REBAR | |

| Material | Steel | GFRP |

| Ultimate tensile strength | 450 | 1100 |

| Modulus of Elasticity | 200000 | 55000 |

| Elongation | 25 | 2.2 |

| Density | 7.8 | 1.9 |

| Thermal conductivity | 48-58 | 0.25 |

| Produce profiles | 6mm – 80mm | 4mm – 50mm |

| Length | Rod lenghts of 6-12 m | Any length required |

| Longevity | In accordance with building standards | 80 years + |

| Bond Strength | 14.5 MPa | 13 MPa |

| Bond Stress | 2.5 MPa | 5 MPa |

The manufacturing of bent GFRP (Glass Fiber Reinforced Polymer) rebars follows a similar extrusion process, but with a critical difference in the curing stage. Instead of fully solidifying the extruded material, the GFRP is maintained in a partially cured or “green” state, allowing it to retain sufficient pliability for subsequent bending operations. This semi-solid state enables the GFRP rebar to be formed into various shapes and configurations, such as hooks, stirrups, or custom-designed geometries, as per project requirements.

As GFRP Rebars are brittle rigid material (Ductibility Low) and break at the ultimate point, it can’t be bend at site like steel. So, the bend bar can be factory made according to our manufacturing process with client specifications, design & drawing.

GFRP rebars offers many advantages over steel rebars. The general properties of Steel reinforcement differ from GFRP REBARS and design engineers consider the same when they design the construction structures. Designers use and refer to ACI 440.1R-15 when they design the structures.

| Straight Rebar | Tensile Strength (MPA) | Ultimate Load (KN) | Tensile E-Modulus |

|---|---|---|---|

| 8mm dia | 1000 | 50.27 | 50 |

| 10mm dia | 1000 | 78.55 | 50 |

| 12mm dia | 1000 | 113.11 | 50 |

| 16mm dia | 1000 | 201.1 | 50 |

| 20mm dia | 1000 | 314.2 | 50 |

| 22mm dia | 1000 | 380.1 | 50 |

| 25mm dia | 1000 | 490.9 | 50 |

| 28mm dia | 900 | 554.4 | 50 |

| 32mm dia | 900 | 723.6 | 50 |

| 34mm dia | 850 | 771.8 | 50 |

| 40mm dia | 850 | 1005.6 | 50 |

ARC FRP products meet industry standards, ensuring quality and compliance for durability, safety, and performance in construction.

Download

ARC FRP products come with an in-house test certificate documenting performance, quality, and compliance based on internal testing and evaluations.

Download

ARC FRP products come with a third-party test certificate verifying independent assessment of their quality, performance, and adherence to industry standards.

DownloadDiscover answers to your questions about ARC FRP rebar, a Glass Fiber Reinforced Polymer used in concrete structures. Learn about its benefits, manufacturing process, applications, and how it compares to traditional steel rebar in terms of performance and durability.

GFRP rebar stands for Glass Fiber Reinforced Polymer rebar, a type of reinforcing bar used in concrete structures made from glass fibers embedded in a polymer resin matrix.

GFRP rebar is produced using an extrusion process. Straight rebars are fully cured during extrusion, while bent rebars remain partially cured to allow shaping before final curing.

Benefits include corrosion resistance, extended service life, lightweight with high strength, non-conductive properties, and cost savings due to reduced maintenance and repair needs.

GFRP rebar is twice as strong as steel in tensile strength, up to seven times lighter, and rustproof, offering enhanced durability and efficiency over traditional steel rebar.

ARC GFRP rebar is well-suited for various applications including masonry walls, concrete roads, drainage systems, foundations, friction slabs, crush barriers, bends in diaphragm walls, piling, precast elements, retaining walls, swimming pools, sea walls, and underground tanks.

GFRP rebar is brittle with low ductility, making it unsuitable for on-site bending. It must be factory-bent to meet design specifications.

Yes, GFRP rebar is non-magnetic and free of ions, making it ideal for areas near magnetic apparatus, such as MRI rooms and electronic testing devices.

GFRP rebar lowers carbon footprints by reducing repair needs, enhancing durability, and promoting sustainable building practices through greener construction solutions.